PRODUCTS

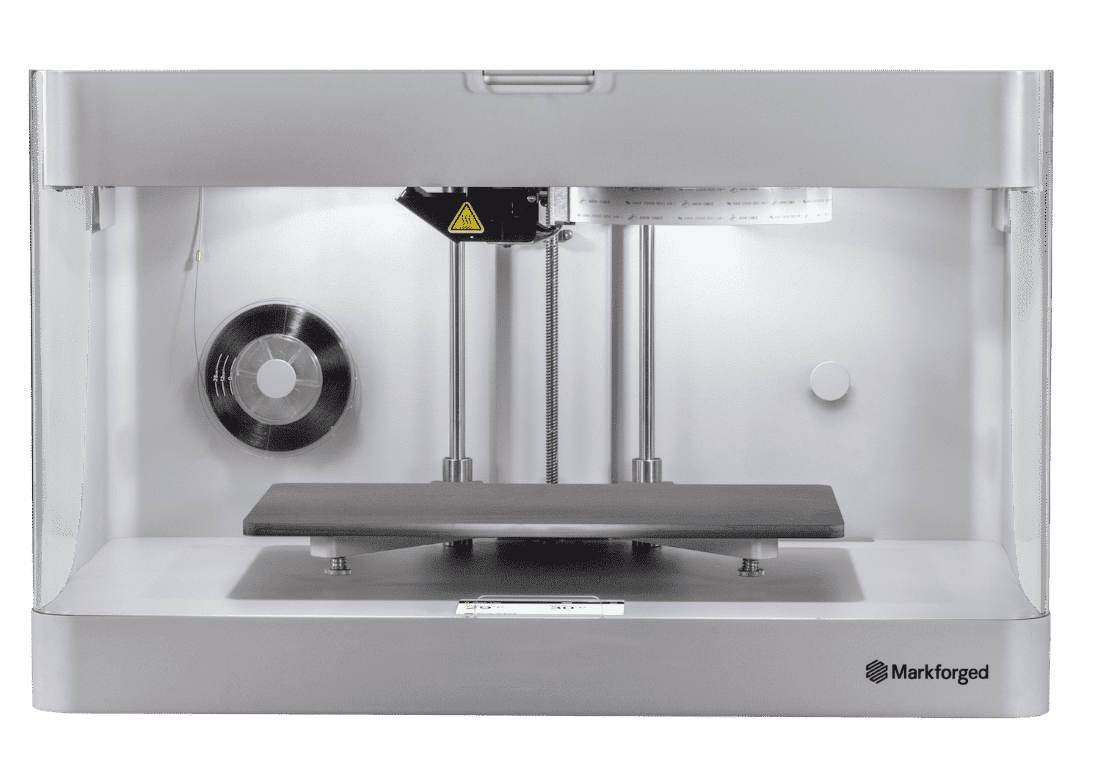

Markforged Desktop Series 3D Printers

Built on the DNA of the Industrial Series Printer in a package that fits on your desk. The Engineering series combines industrial quality and affordability in an all aluminum frame to uniquely create stiff chopped carbon fiber parts with a beautiful surface finish and high chemical resistivity. Onyx material is the core material for all Markforged composite printers, Onyx is a proprietary material from Markforged that combines nylon with chopped carbon fiber and is twice the strength of other 3D printed plastics. Great for industrial applications like functional prototyping and end use parts. This series printer won enterprise printer of the year in 2017.

Mark Two

The Mark Two is the top of the line engineering series printer that has the capability to print composite parts that are as strong as aluminum, Replace machined aluminum tooling – jigs, jaws and fixtures – with stronger parts for a fraction of the price. The Mark Two combines Markforged’s unique continuous carbon fiber reinforcement with workhorse reliability for versatile parts with 23x the strength of ABS, ready same-day for use straight off the printer. Formed from the combination of two materials, composite parts are incredibly strong and versatile. This unique fabrication process from Markforged enables you to print parts that are an order of magnitude stiffer and stronger than typical 3D printed objects.

Onyx Pro

Onyx One

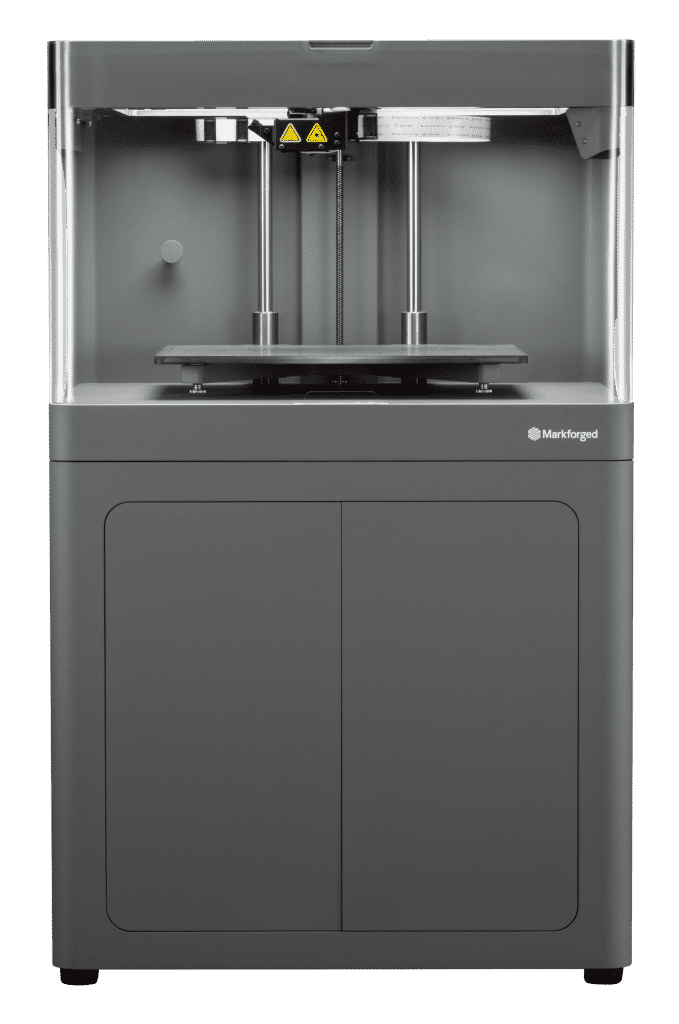

Markforged Industrial Series 3D Printers

The Markforged Industrial series printers provide unparallel accuracy, repeatability and reliability. With the ability to print exceptionally strong parts, the Markforged Industrial series printer is a perfect fit for every manufacturer. These printers provide a low cost and lights-out solution for applications like fixtures, jigs, tooling, functional prototyping, and end use parts. With the ability to print at 50 micron resolution, your parts will come out with an incredible surface finish with the look and feel of injection moulding.

FX20 Industrial

X7 Industrial

The X7 features a strengthened dual nozzle that supports continuous carbon fiber and Kevlar reinforcement, with the added carbon fiber and Kevlar the top of the line X7 3D printer has the capability to produce parts that can stand up to the toughest of applications, from replacing machined aluminum parts with loaded carbon fiber parts to replacing traditionally machined end of arm tooling with impact resistant Kevlar.

Formed from the combination of two materials, composite parts are incredibly strong and versatile. This unique fabrication process from Markforged enables you to print parts that are an order of magnitude stiffer and stronger than typical 3D printed objects.

Laser Precision – With a built-in laser micrometer, the X7 automatically scans the print bed with 1µm accuracy to generate a contour map of its surface. By calibrating its measurements with extrusion readings to perfectly set nozzle height and active topography adjustment, the X7 ensures your prints come out exactly how you want them.

X7 Field Edition

X7 FE extends the reach of the Digital Forge, helping you produce parts with minimal effort at any point of need.

Simple user interface for effortless print configuration, with onboard

utilities for guided printer calibration and maintenance. The X7 FE can be fully set up and ready to print in minutes. The unit contains the materials, spare parts, and tools needed to sustain production between

resupply opportunities.

Increase supply chain resilience by printing tools, adapters, and replacement parts for equipment at the point of need. Ensure dimensional accuracy for the most critical tolerances with the integrated laser micrometer and adaptive bed leveling.

X3 Industrial

The industrial grade X3 printer starts with an all aluminum unibody encloser built around an ultra flat gantry system, machined aluminum stage with kinematic bed coupling and a precision ground print platform. The X3 uses chopped carbon fiber filament reinforcement to produce parts that are 20% stronger and 40% stiffer than ABS. Resistant to impact and a wide variety of manufacturing chemicals. These heavy-duty parts stand up to abuse. The X3 is built to thrive in the manufacturing environment, fully instrumented with motor encoders and a laser micrometer 3D scanner so accurate it can compensate for single digit changes in room temperature. The X3 is a cost-effective 3D plastic printer that meets the needs of a huge range of industrial applications.

Laser Precision – With the built-in laser micrometer, the X3 3D plastic printer automatically scans the print bed with 1µm accuracy to generate a contour map of its surface. By calibrating its measurements with extrusion readings to perfectly set nozzle height and active topography adjustment, the X3 ensures your prints come out exactly how you want them.