Case Study

Stanley Black & Decker

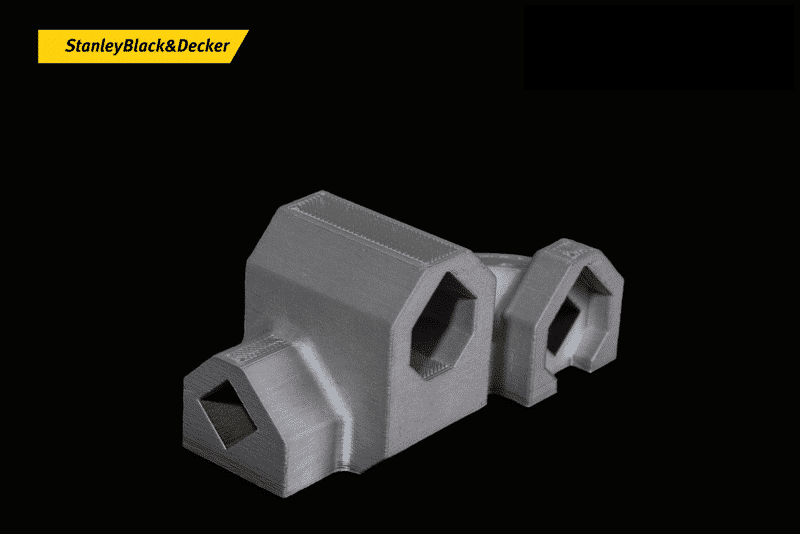

Engineers from Stanley Black & Decker are searching for a cost-effective way to manufacture low volume, complex parts. After exploring metal 3D printing technologies, Stanley Black & Decker chose Markforged’s new Metal X additive manufacturing technology to produce reliable, 3D printed production parts and slash their capital costs and lead times.

Download the case study to analyze the part and performance comparison from Stanley Black & Decker’s original parts versus the parts printed on the Metal X 3D printing system. You’ll see why their engineers believe they can save thousands of dollars per year on just one 3D printed part, while replicating the part quality and reliability they expect from machined parts.