Build volume is a concern especially for industrial fixtures and prototypes. Companies often will spend $100,000’s of dollars for larger build volume 3D printers.

I created an example of how to design custom dowel connectors that will fit snuggly between joined parts. With an application of glue or epoxy the joints will be stronger than the rest of the part.

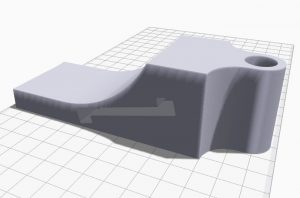

For this example I used with permission a slice of part designed by Saber Bytes Robotics for their First Robotics competition that I had previously printed;

I started by designing a simple shape that could be scaled to fit different size part in the future;

While the printing material, Onyx, has chopped carbon fiber so the walls provide sufficient strength for the connector, I added some strands of continuous fiber for an even stronger demo;

Next in CAD you need to drop the connector into the part in the location the part will be split for printing to subtract and create a space. In order to ensure snug fit of the connector, I enlarged it by only 0.2mm on the X and Y cross-section that it will be inserted. I added 2mm to the width to ensure the two halves are joined with no space.

Once the space has been created inside the part, you can select the line to split without spending a lot of time making sure the printed parts will align when joining them together.

Here is a video of how the two halves for my demo are put together;

After checking the fit you can apply an adhesive such as Loctite 401 to ensure a permanent strong assembly.

There are several reasons using Markforged printer for large parts can be a superior alternative;

1) Cost – You can purchase many printers at a fraction of the cost of one large printer.

2) Repeatability – in this example I measure the height of the two halves printed in two separate build with different orientation

3) Post Processing Effort – The amount of post processing effort is less with Markforged as the parts are easily scraped off the build plate and supports are removed mechanically in a few minutes with no chemicals or mess. As you can see from video above the assembling of sections takes little effort.

4) Strength & Quality – Markforged Onyx material alone makes strong parts and with the option to use fiber where needed, allows for unique better solutions. The superior design of gantry, use of precision machined parts and software allow for impressive results on complex shapes.

Kelcom 3D division is an authorized reseller Markforged 3D printers and provider of 3D printing services in Windsor-Essex, Chatham-Kent, London – St.Thomas, Kitchener-Waterloo, and Sarnia, Ontario.