Introducing the Mark X

Uncompromised Strength, Precision, and Beauty

In 2014 Markforged announced their first Continuous Fiber Fabrication 3D printer, designed to reinforce 3D printed plastics for unmatched strength. Now they combine advanced sensing systems with a large build area to create the Mark X. Drive innovation, efficiencies and revenue at your company by transforming product workflows with a revolutionary printing platform

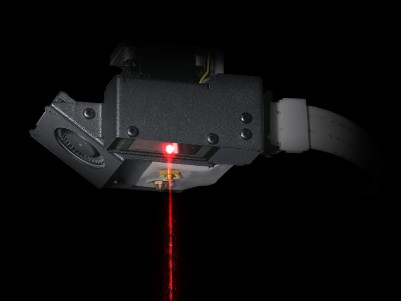

Part Quality Confidence

Ensure dimensional accuracy at the most critical tolerances with the unique mid-print laser inspection capabilities of the Mark X

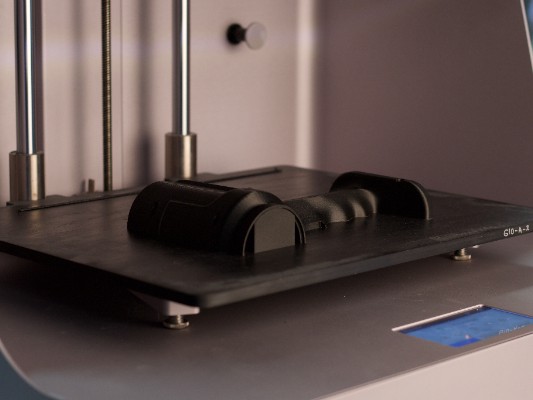

Industrial 3D Printing for Any Workspace

Despite its large build area, the small footprint of the Mark X is suited well for both the office and the shop.

Revolutionizing the Supply Chain:

- 330 x 250 x 200 mm build volume (XYZ)

- Out-of-filament and jam detection system

- Laser displacement sensor for mid-print inspection

- 50 micron minimum Z Layer resolution

- 50 micron XY resolution

- Online slicer with customized fiber layout options

- Print in Tough Nylon or Onyx, a micro-carbon reinforced plastic filament

- Reinforce plastics with continuous fiberglass, Kevlar, or carbon fibers